As with all of our workshops we host here in Yarrow, we are making name plaques for all of our attendees. Each will be unique. The name plaques serve a variety of important purposes. They are a wet of welcoming our guests and showing our appreciation for them traveling to our studio for our workshops. They demonstrate the variety of routing techniques we can achieve using EnRoute Software.

The name plaques also serve to sharpen my own design skills and re-acquaint myself with every aspect of the software. Each time I sit down to design and create twenty-five (or more) plaques I find I learn lot in a hurry. The challenge was to create similar sized but unique name plaques, each measuring about a foot square and one and a half inches thick. Each was milled from 30 lb Precision Board.

Though the next series of posts I will take you through a number of the name plaque projects. I encourage everyone who wants to learn to use EnRoute proficiently to do similar projects for family and friends. The more you do the better!

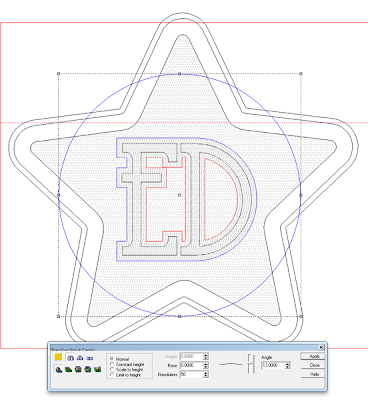

The first plaque is a simple one that uses a variety of techniques. It was for Ed. I decided a star shape was the starting point. This file was created entirely in EnRoute Pro 5. I didn't grab a screen shot of the starting vectors but they are shown below in other shots.

The first step was to use the bevel tool to create a star relief. I recall it was at a shallow angle of about ten degrees. The sides (base) of the star were 0.35" tall.

Then I added a splotches texture from the TEXTURE MAGIC collection. I used a value of 0.15"

Then I created the letter outline as a separate flat relief with a thickness of 0.6"

I then modified this flat relief using the circle vector. Once I had my rounded relief I went to the front view and nudged it into place vertically.

I then merged (highest) the letter outline with the star relief.

Then, again using the bevel tool I created the prismatic lettering. Make sure you select the base relief and modify it with the lettering vectors. The base (vertical sides) of the letter was 0.15 and the angle was relatively shallow at 18 degrees.

I cut the star from 30 lb Precision Board using two bits. The first roughing pass was a 3/8" ball nose bit with a 50% overlap. The final pass was using a 1/8" tapered bit at 80% overlap. Both tools were set at 300 inches per minute on our MultiCam. The file tool about twenty minutes to run.

Stay tuned for a whole series of similar projects - all unique.

-dan