For Torey's name plate I wanted it to look like boards fastened together. I toed out the letters, learned and sized them appropriately then whipped out the rectangles that would become boards. I wasn't worried about sizes or spacing at this point.

I then selected odd number boards and assigned them a height to create the reliefs.

Even number boards got the same treatment with a slightly different height.

I then imported the sandblasted wood bitmap. This bitmap is based on an actual photo of five laminated boards. I positioned the four rectangular reliefs over the boards sizing them to fit on the different pattern boards, assigned a value of 0.15" and added the textures.

I then duplicated two I liked, rotated them 90 degrees and resized them to suit. I also resized and arranged the original four boards at the same time.

Then it was time to add some height to the horizontal boards.

I didn't want the spaces between the boards to be hollow (for strength reasons) so I created a flat rectangular relief and positioned it vertically under the boards.

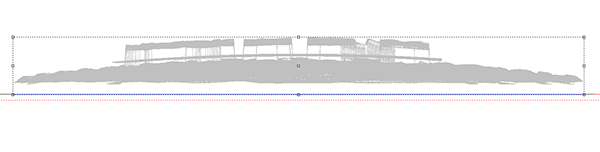

Before combining the reliefs I checked the height of all the elements in the front view.

I then combined the vertical board and the lower relief.

Then I combined this relief with the horizontal relief. I also added an offset border around the letters which was made into a nee flat relief.

Since I just guessed at the height this lettering border needed to be I checked it in the front view. It was much too high so I nudged it down using the arrow keys.

Once I has happy with it's position I then merged highest with the base relief.

The last step was to modify the base relief by adding the lettering.

The Torrey name plate was ready to sent to the MultiCam. As always it would be routed from 30 lb Precision Board.

-dan