The folks at Coastal Enterprises (Precision Board) needed a new display for the trade show coming soon. They had seen the latest article in SignCraft featuring the Kel-Mor dump truck and wanted something like that - only much smaller. I sent them a picture of a small sample sign I had done and they asked me to do a similar concept drawing.

The concept showed a small flatbed truck with Precision Board samples stacked on the back. We had an instant GO!

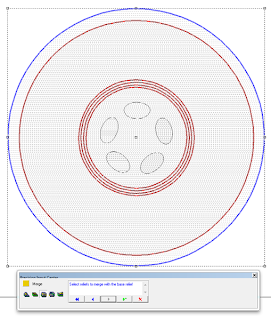

As I worked up the vectors for the piece I decided to make it a tandem truck. The first job was to create the ten wheels I needed. As a bonus I added the company name to the tire sidewalls.

The I created the rim edge as a separate flat relief.

The raised lettering was the next order of business, created by modifying the tire relief by ADDING TO.

I then added the wheel center using the dome tool.

The wheel slots were created as zero height reliefs and then MERGED LOWEST to the wheel assembly.

The truck vectors were then designed around the wheels to get the proportion correct. I used these vectors to build the reliefs and to cut out the many pieces of Precision Board we would need for the assembly. I then sent the files to the MultiCam and in short order we had all of the pieces we would need for this project.

In the next day or so I'll be gluing it all together. Then the hand work can begin. Stay tuned...

-dan