As we wrap up the painting in the MultiCam board room I am turning my attention to the details which will abound in the room. Last week I whipped up the door trim which instantly turned the doors from ordinary to something befitting this room.

On the inside I used the MultiCam to cut some MDF in a shape mirroring the white board door. I fasted this to the plain door and then used the circular hole in it as a template to cut the portholes in the door. Another simple shape I had routed formed the inside and outside trim with the plexiglass sandwiched in between. A few dozen rivets cut from 30 lb Precision Board finished things off. The doors will be painted a copper color with lots of weathered patina to age it appropriately. The outside of the door is relatively pain with only the portholes sneaking into the hallway. I suspect a colorful starfish will slither out into the hallway too - much to the chagrin of the interior designer.

Yesterday the owner brought in the large LED TV which will be mounted to the end wall opposite the white board. I measured the big TV carefully and took notes too. It simply can't be left stock as it has to fit into the theme of the room. Over the next days I will be building a frame which will surround it. The key is to not block any venting or disrupt the operation of the TV controls. Here's the concept drawing.

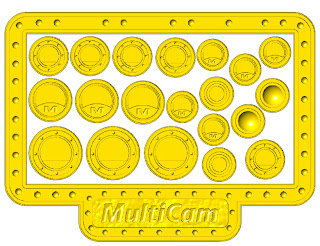

Since the gages and the liquid tube will be lit with LED's I had to figure everything in as I designed. The vector and routing files were created in EnRoute. There will be an 'M' embossed into the face of the gages just to continue the theme to the max. I'll print some faces for the gages and glue them in as we assemble the TV surround, along with some plexiglass.

I'll let the file run on the MultiCam as we go to spend one last day at the site before the cork floor goes in on Monday. There is an extra gage for the white board in the same routing file.

The room is gaining notoriety locally as word spreads from the trades working on site. Each day we get more and more folks visiting to get a first hand look. The owner is bringing every prospective client by to look things over and show them the amazing things that can be done with a MultiCam.

It is working beyond expectations already - just as I figured it would. Build it and they will come!

-dan